Handling-Tips

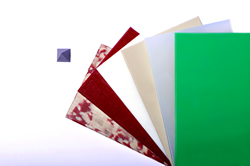

Cutting boards in production or in stock as a spare part are often not used or stored as required to get the maximum life available. We have provided information in our handling tips that will show you how to dramatically increase the life of your cutting boards as well as help you recognize the difference between a normal cutting board and a very high quality cutting board.

| Please remove packing after receiving your cutting board. Stock the cutting board flat on a pallet if it not going directly into production. Protect the cutting board from excessive heat, caused by sun or by heaters. Cutting boards are made of thermoplastic plastic and they will bend before usage, and if they get over heated are not laying flat. | |

|

|

Please adjust the cutting machine very accurately. You have to take care that the cutting board is flat on the cutting press table and the cutting die is moving retangular to the cutting boards.Therefore you have to controll the cutting knife and the movement of the cutting press head. |

| Die cutting always occurs on the surface of the cutting board. There is no advantage for cutting deeper than neccessary to make the cut. Cutting to deep can cause material to be pressed into the cutting board, can cause the cutting die to stick into the cutting board and will definitely cause accelerated wear. If the cut is not clean at the surface and your cutting press and dies are parallel you should use a harder durometer cutting board from our product range. | |

| Please try to utilize the complete board surface. Partial cuttings will lead to voids in the cutting boards and prevent clean cutting in the area of the void. | |

| Even very high quality cutting boards have some tension inside. Please rotate and flip the cutting board as often as possible in order to keep the flatness of the board. Continued use of the board on one side will cause the cutting board to bend. Dull cutting dies will also cause the material to yield and will introduce tension into the cutting board causing warping, bending, or deformation. |

| Die Stanzunterlage biegt sich und macht ein normales Stanzen unmöglich. |