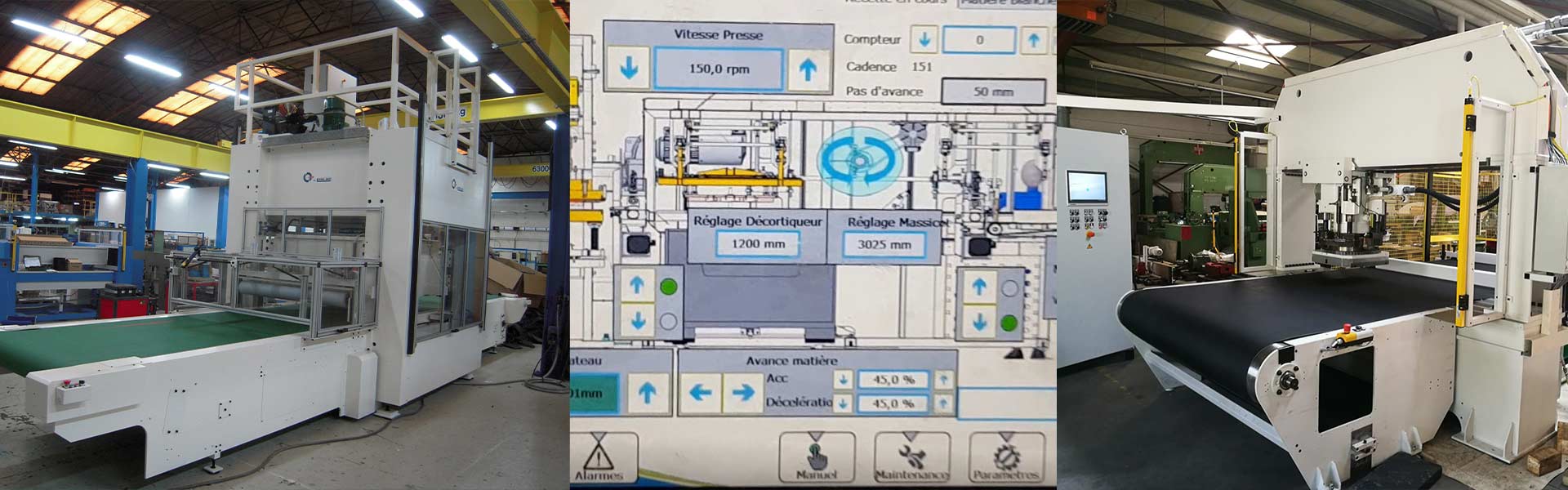

A beam press with a fixed beam is a comfortable die-cutting machine for large industrial production volumes and is the complement to a receding head beam press with a mobile bea,. The cutting head only moves up and down and the material to be punched has to be brought under the punching head, which is done by slide-in tables, roller or clamping bar drives and/or punching belts.

With a beam press with a fixed beam, the punching head always covers the entire punching area, roll goods or sheet goods can be cutted and the cutting tool is attached under the cutting head – either manually or automatically.

cutting force 30-500 Tonnen/tons

cutting bed 600 x 900 mm up to 3.000 x 3.000 mm

cutting head 600 x 900 mm up to 3.000 x 3.000 mm

stroke 110 mm – more on request

automatic diesetting

cutting head is going up and down and cutting tool is under the cutting head

– cutting of leather

– cutting of foam

– cutting of felt & non woven

– cutting of plastic film – with or without adhesive

– cutting of self adhesive tape

– cutting of paper and cardboard

– cutting of all materials, which are possible to cut with scissors

– etc.

Why use a Beam Press?

There are many different feed systems available with Beam Press Cutting Systems.

Beam Presses may be used for high or low volume production for cutting both roll and sheet materials – single or multi layered. Beam Presses can have manual or automatic operation dependant on feed system.

A wide choice of different models

From the smallest 25 Ton to the largest 500 Tons or more on request, Suteau Beam Presses are adaptable to a wide range of applications. Suitable for cutting a wide range of materials, including:

Value for money with no hidden costs

Our Beam Presses are sold ‘ready to run’: complete with power lead, cutting surface & instruction manual.

Flexibility & Ease of Operation

Designed for maximum flexibility when using roll or sheet material, small or large tooling. No special skills are required to operate these presses. They are specifically designed to reduce operator fatigue. Excellent vision of the work area and simple operation ensures the operator is in control at all times.

Peace of mind with our fast back-up service

Suteau Beam Presses offer you reliability. Our team of service staff are always available to help you with queries and advice. We are keen to respond quickly to your needs with engineer on site support and fast spare parts back-up.

Efficiency

Maximum force is achieved using minimum electrical power consumption – this greatly reduces your running costs.

Robust Construction & High Accuracy

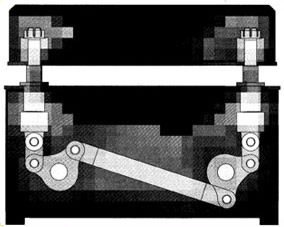

Presses are solid construction for durability & long life. With minimum deflection these presses are designed for maximum speed and high productivity. Built to cut the toughest jobs 24 hours a day. Supplied with LVDT transducer for maximum cutting depth control and our unique balancing system, the head and bed stay parallel at all times for maximum cutting accuracy.

Quality Features

Balancing System

LVDT Transducer

Standard Feed Systems

SWork Tray Feed

An economical system for cutting materials. Tooling can be laid on the tray or free placed onto the material. Very simple to use. Available as single manual work tray, double manual work tray, single motorized work tray or double motorized work tray. The double tray systems have independent controls and individual knife setting on each tray for maximum output.

Cutting Belt and Pinch and Grab Material Feed System

This is an extremely versatile and fast cutting system. Suitable for medium and very high volume production.The belt feed system allows non-rigid and difficult materials to be fed into the cutting area more easily. Tooling is normally mounted directly onto the cutting head. Latest keyboard control, simple to operate, capable of storing upto 250 programs for instant job recall, storing such information as: feed distance, cutting pressure, daylight etc…this speeds up job changeover.

Once the job has been set, the machine starts cutting and automatically feeding forward, the machine dictates the speed of production for maximum output. The cut parts are collected on the outboard side.

The high quality belt can be changed with minimum disruption, large diameter rollers and tracking system ensure the belt is always kept in the best possible condition. Unbeatable belt life is attained owing to minimum deflection of the press and the setting of positive mechanical stops.

The option of a removable work tray may be added to this system for maximum versatility.

Extended Tray Feed System

This system is best employed for cutting groups or sets of components. Often used with large multi-cavity cutting tools or sets of strip tools which are incremented through the press.

This system may be manual or fully automatic and can be designed to accommodate any die board or cutting board length to suit your production.

Inboard and Outboard Material Feed Rollers

This system is ideal for cutting sheet materials in high volume, such as packaging foam. The system can be fitted with take-off belt and lazy loop system for cutting in-line production. The take-off belt presents the cut parts to the operator for easy removal of components. The lazy loop allows your material to be fed into the press in a relaxed state for maximum cutting accuracy.

Multi-Work Station System

The multi-work station system allows maximum cutting of high volume production. The number of work stations can be tailored to your requirements. This fully modular system can be extended at anytime for increased output. Die Boards or Cutting Boards of any size can be accommodated. Often used for cutting leather for the automotive or furniture industry.

Options

Beam Press Systems can be supplied with a range of ancillary equipment to enhance your productivity:

Please contact us today for all your requirements

We like it to advise you free of charge, which cutting press is the best for your application!

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information