Full Automatic cutting plotter with integrated loading – cutting – unloading system for packaging and display.

Kombo TAV is the flexible and modular, innovative dieless cutting system, with two indipendent cutting heads and material handling integrated in the production cycle. Among its various original and innovative solutions, Kombo TAV it is the first step to the true complete workflow automation and guarantee a production increase and the cost reduction whilst offering a non-stop working not to be found in any other dieless cutting system.

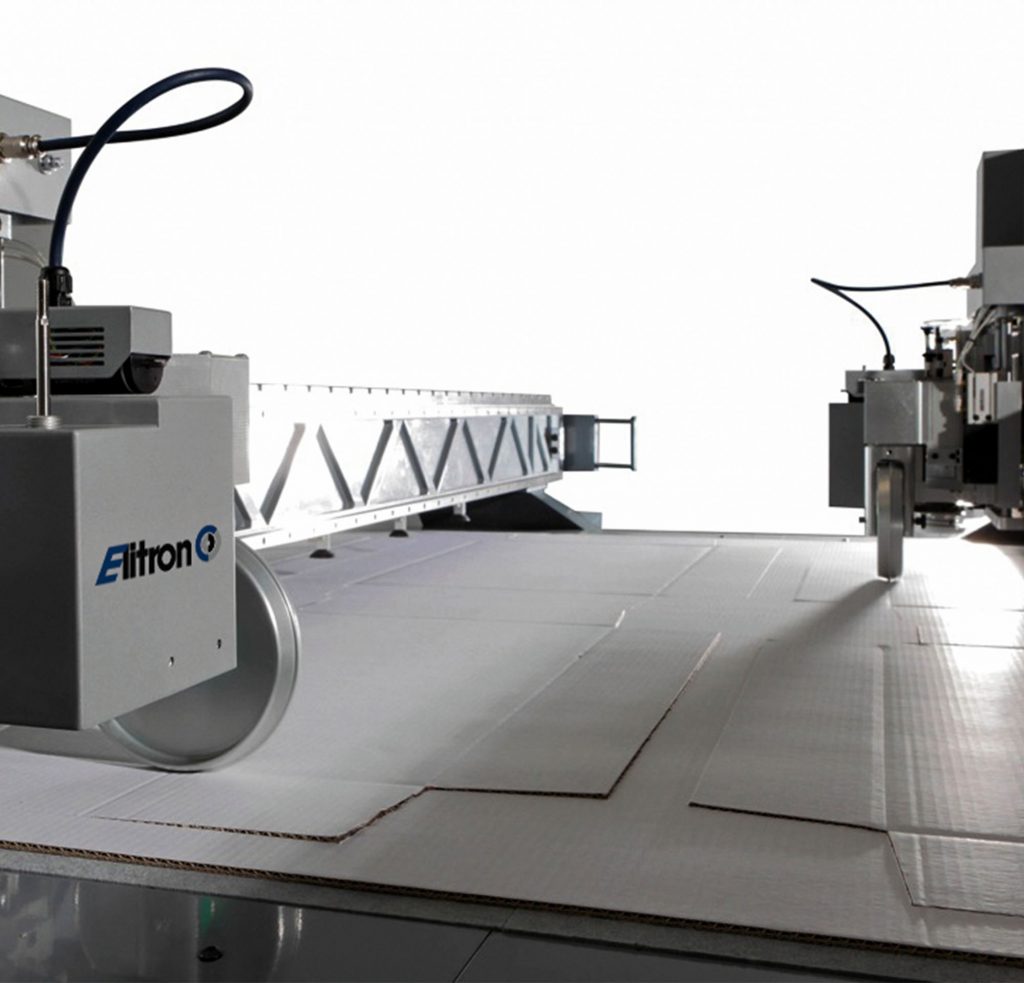

Kombo TAV is the only plotter with two independent cutting heads to accelerate production times with more jobs being processed in less time. This flexible dieless finishing system cuts production times and reduces costs whilst offering maximum versatility for both short and complex production runs. The innovative integrated loading and “AiroPanel” unloading systems – patented by Elitron – fully automate the entire production process, reducing costs, for a non-stop workflow. KOMBO TAV is the only plotter that comes ready to install a fully motorised roller loading system. The system can also be raised to take a pallet of up to 1380mm high, thanks to this option more material can be loaded for increased productivity.

Kombo TAV-R represents the cutting department state of the art. In the most complete version, full automation results in an elaborate motorized materials handling system, exclusively developed by Elitron. The effect is a high-performance cutting system that will revolutionize the concept of integrated automation in the company production cycle, both with other Elitron’s products and with third parties’ products. A real 24/7 production without operator.

Wide flexibility through the multi-sheet loading management and the selection of the feeding modes: by lifting table, by carriage, up to the roller conveyor automatic feeding. Possibility to load up to 120 cm of material

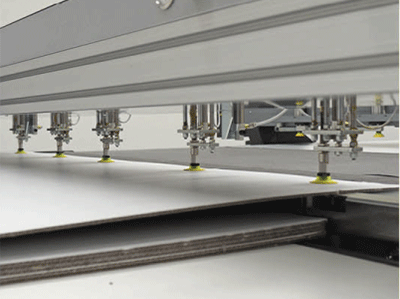

The sheets positioned onto the pre-loading area are read from below, using Seeker System, the dual camera vision system patented by Elitron, which detects the reference points for a perfect synchronization of the cutting path with the printing. Seeker System also identifies the barcodes/qr code for the automatic loading of the relevant cutting files.

The pre-loading system reduces the downtimes optimizing the material loading, preparing the reference points detection and positioning the material in a stand-by zone, all while the two cutting heads work.

Maximum productivity thanks to the two independent multi-tool cutting heads operating simultaneously on the whole cutting area. Elitron’s TwinCut software calibrates and assigns the workload to each of the cutting heads, optimizing the overall time. Cutting and creasing of materials up to 20 mm thick.

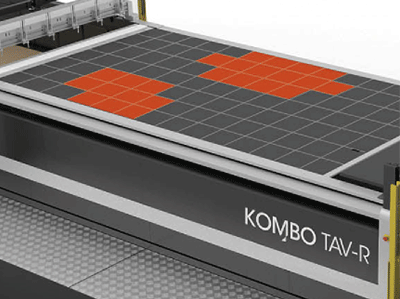

Cutting area up to 3200 x 2200 mm with suction surface made up of 24/32 sectors for the perfect adherence of the materials, even the most critical ones.

High cutting quality for the absence of unsightly nicks, no longer needed, and easy scraps removal.The whole working area, whether loaded in single or multi-sheet, is fully unloaded in one go through Airo Panel, an exclusive Elitron’s Patent, powerful panel that sucks all the processed sheets at once, carries them to the unloading area, stacking them onto a pallet.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information