Do all cutting boards have the same quality?

We could easily answer this question «no». There are many different plastics with different properties and of course different prices.

We could easily answer this question «no». There are many different plastics with different properties and of course different prices.

The first difference is the raw material. High quality raw material is in general more expensive than low quality raw material.

The second difference is the production speed. The faster the production speed the more tension will be inside the finished product. These tensions will ultimately reduce the lifetime of the cutting board.

The third difference is the choice of the additives. With additives you can influence the properties of the material. It is imperative that the proper additives are used to get the very best solution for a particular application. A very good cutting board must manage the opposite requirements of

- max. surface hardness

- max. elasticity

There must be compromise in order to archieve this.

Maximum surface hardness

Maximum surface hardness

In 99% of the applications you could follow this advice : «The harder the cutting board, The better the cutting result.»

Maximum elasticity

This second requirement is very important and will help protect expensive cutting dies when a cut is made to deep. Elasticity is also needed for «self healing» during cutting. (Self healing means a previous cut will be closed when a new cut is made next to it. This will extend the life of the cutting board).

Compromise

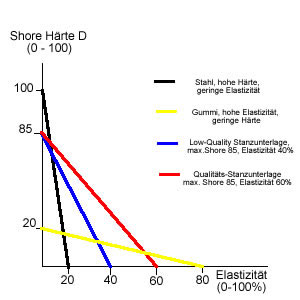

Only very high quality cutting boards have a compromise of these opposite requirements at the highest level possible. In the cutting board market you will find cutting boards from different suppliers with the same colors and same shore D hardness. These boards appear to be the same but can be different due to the compromise. The following illustration will help define the differences.

A steel cutting surface is very hard and has a low level of elasticity. You would get the best cutting results in the beginning but the cutting edge will become blunt over a short period of time. If a cut is made to deep the cutting die can be destroyed.

A rubber cutting surface is very elastic and has a low hardness. It would protect your cutting die But the cutting result would not be acceptable. The material will be forced into the surface as you make the cut.

A low quality cutting surface made of plastic with a shore D hardness of 85 and minimal elasticity is a better compromise than the steel or rubber sheet alone but does not provide the best compromise. Does not self heal and will crumble easily.

A very high quality cutting surface made of plastic with a shore D hardness of 85 and the maximum elasticity is the best compromise and will give you longer cutting life. This surface will self heal, resist crumbling, and offers the best protection for your cutting die investment.

Very high quality cutting boards will provide you with the best value. They will last longer and minimize your downtime.