Manual Travelling Head Presses

| Cutting Force: | from 20 up to 80 Tons |

| Cutting Bed: | from 1.500 x 500 mm up to 2.300 x 1.000 mm |

| Cutting Head: | up to 1200 x 1200 mm |

We can build to suit your production requirements – we welcome your request for a machine specific to you.

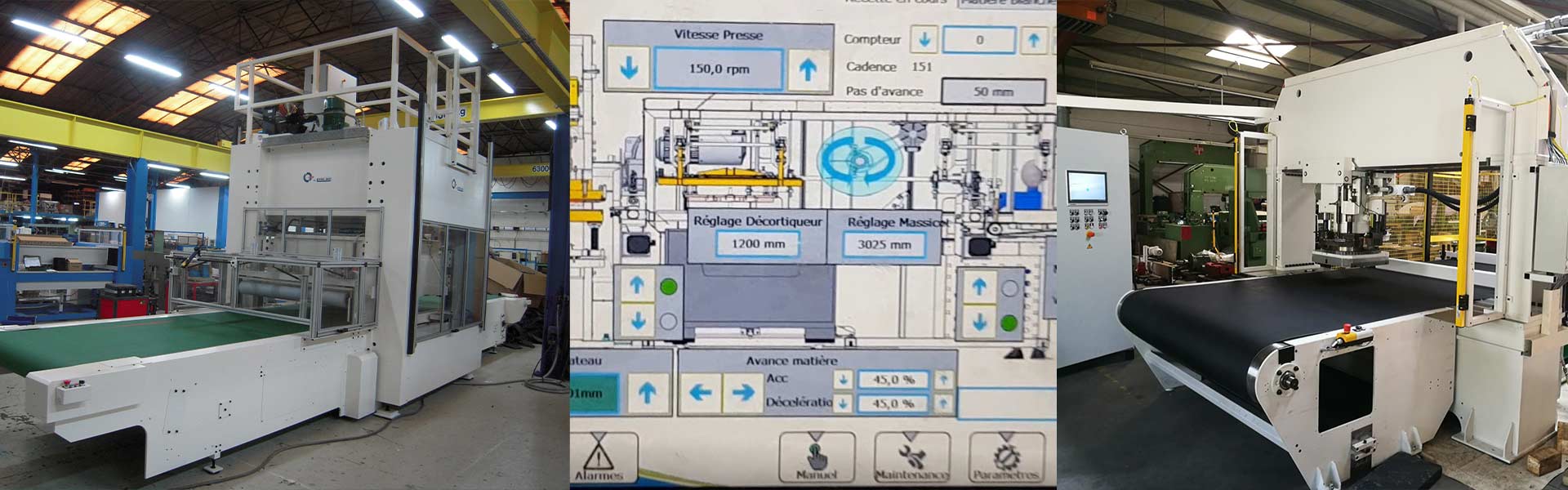

A Travelling Head Press is the next step up from a Swing Beam Press for cutting single or multi shapes from material – single or multi layer from rolls or sheets.

The material and tool are placed under the head of the Travelling Head Press, the operator then presses two push buttons to bring the cutting head down under force to cut out the shape.The Travelling Head automatically moves to the side to allow the operator to reposition the tool for the next cut.

These presses are very versatile and can be used for low or high production capacity.

A wide choice of different models

From the smallest 20 Ton to the largest 80 Tons or more on request, Suteau Travelling Head Preses are adaptable to a wide range of applications. Suitable for cutting a wide range of materials, including:

|

|

Value for money with no hidden costs

Our Travelling Head Presses are sold ‘ready to run’: complete with power lead, cutting board & instruction manual.

Flexibility & Ease of Operation

Designed for maximum flexibility when using roll or sheet material, small or large tooling. No special skills are required to operate these presses. They are specifically designed to reduce operator fatigue. Excellent vision of the work area and simple operation ensures the operator is in control at all times.

Peace of mind with our fast back-up service

SuteauTravelling Head Presses offer you reliability. Our team of service staff are always available to help you with queries and advice. We are keen to respond quickly to your needs with engineer on site support and fast spare parts back-up.

Efficiency

Maximum force is achieved using minimum electrical power consumption – this greatly reduces your running costs.

Robust construction

Presses are solid construction for durability & long life. With minimum deflection these presses are designed for maximum speed and high productivity. Built to cut the toughest jobs 24 hours a day. Larger head sizes are specifically designed to ensure quality cut is achieved when using larger tooling to allow no overhang of cutting plate.

Please contact us today for all your requirements

We like it to advise you free of charge, which cutting press is the best for your application!